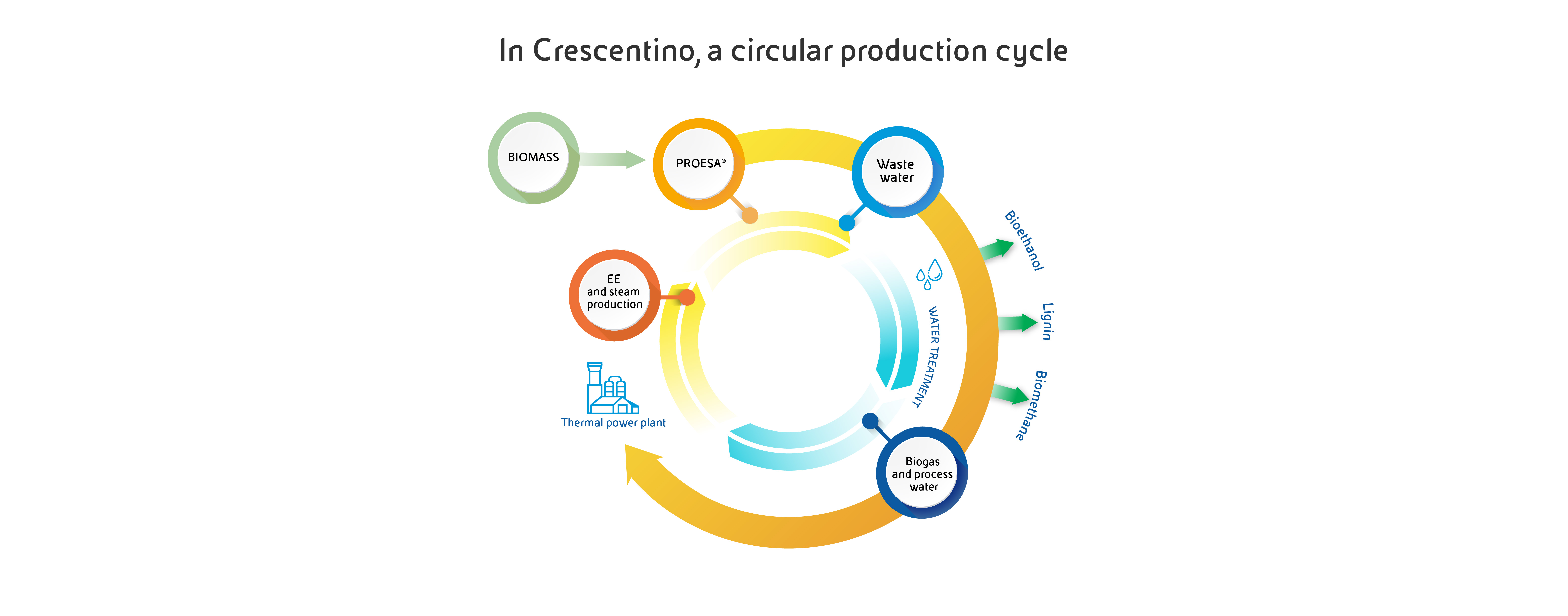

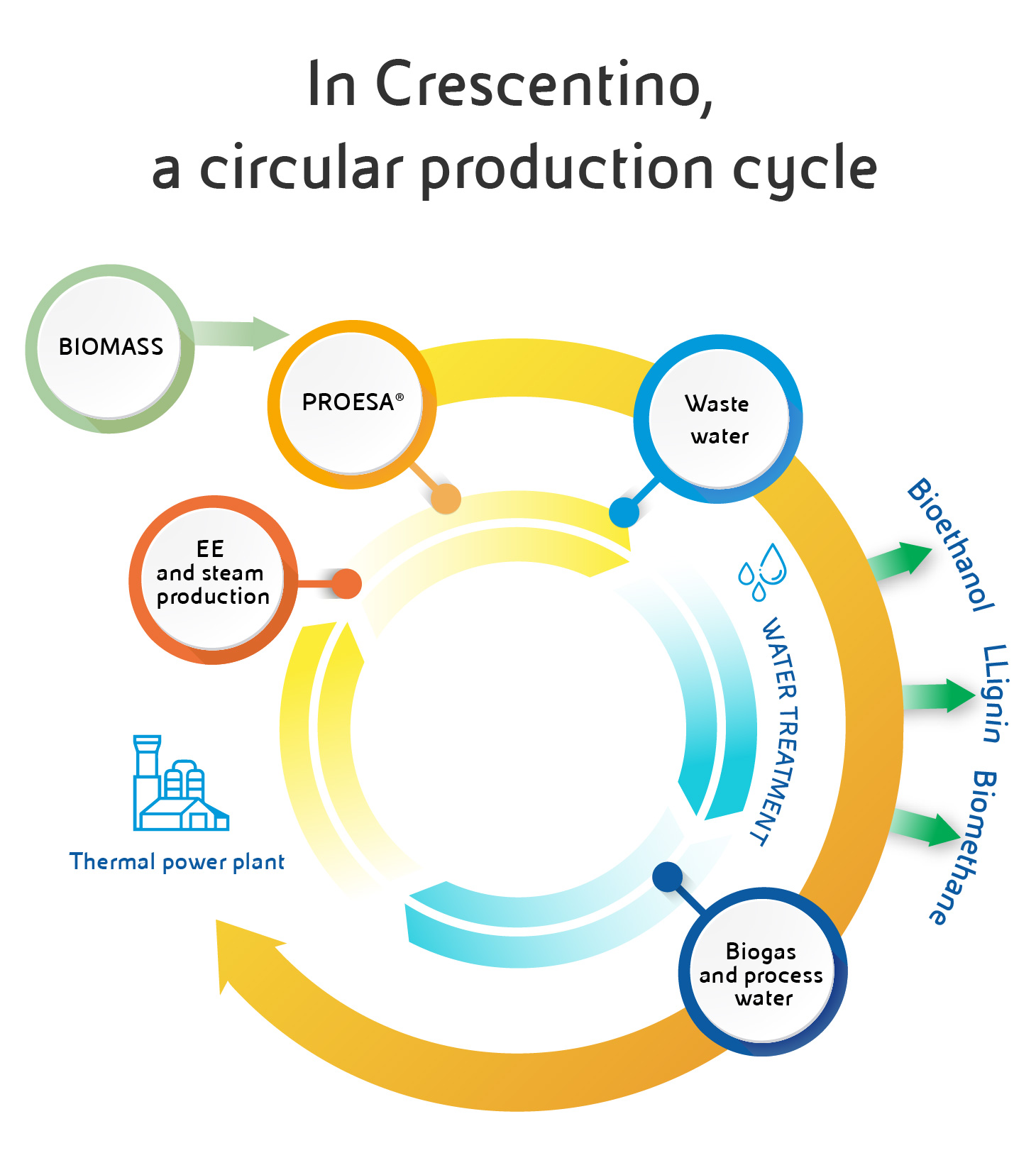

We are constantly engaged in the transition towards the development of a sustainable, low-carbon growth model. That is why we base our activities on integrating the principles of sustainability and circularity in the management of industrial processes and products throughout their entire life cycle.

One of the pillars of our strategy is the development of chemistry from renewables, with the aim of starting from alternative sources to offer decarbonised products.

.jpg.rend.262.150.jpg)