Decarbonisation is a strategic challenge for the chemical industry, one of the most complex sectors to transform due to its high energy intensity. Lowering emissions is an ambitious objective, but also an opportunity: technological innovation is the crucial lever for achieving carbon neutrality. As a result of its key role in numerous global value chains, the chemical sector can become a driver of solutions that accelerate the transition towards increasingly sustainable industries.

We have implemented a decarbonisation roadmap in line with Eni strategy and aim to achieve Net Zero by 2050*.

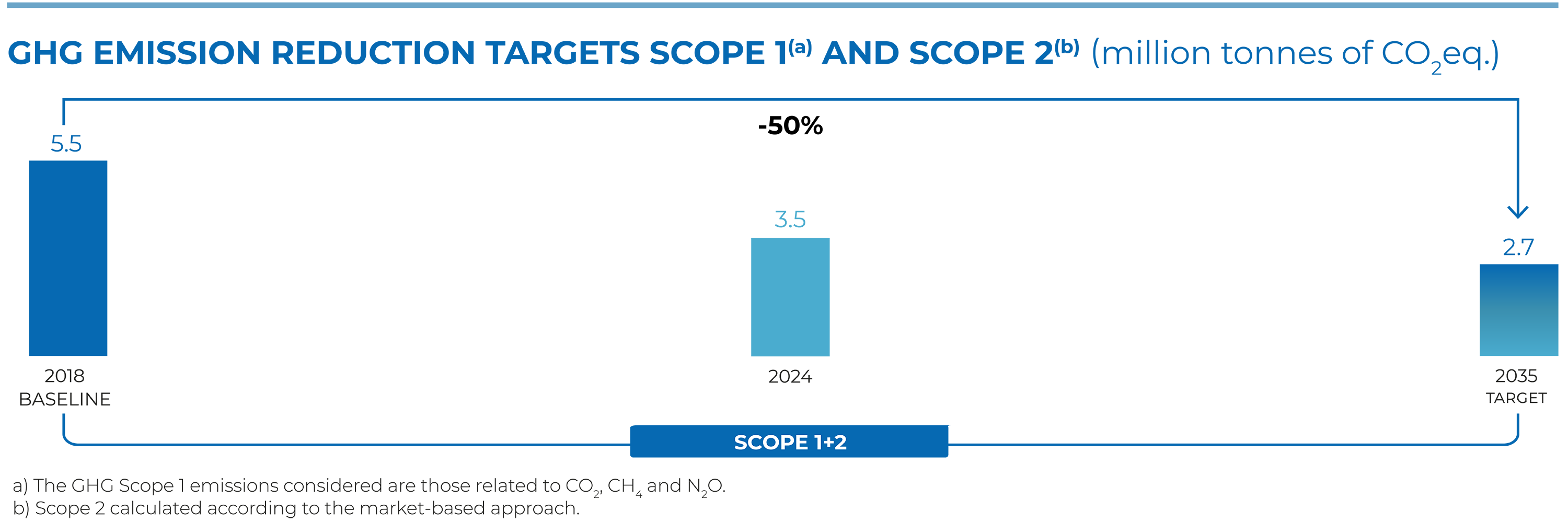

At the heart of this process, we have industrial conversion of assets to bioeconomy, circular economy and specialist platforms for the development of efficient, innovative and hi-tech polymers and products, in keeping with the energy transition and ongoing decarbonisation process. This process began with the transformation of the Porto Marghera industrial site where, following conversion of the cracker in 2022, we have managed to achieve an annual reduction in CO2 emissions exceeding 600,000 tonnes. Furthermore, with the implementation of the transformation plan announced in October 2024 it will be possible to achieve a further reduction of approximately 1 million tonnes of CO2 (Scope 1 and 2**) compared to the current setup.

* The Net Zero target is achieved when residual anthropogenic greenhouse gas emissions (GHG) are counterbalanced by the emissions removed from the atmosphere.

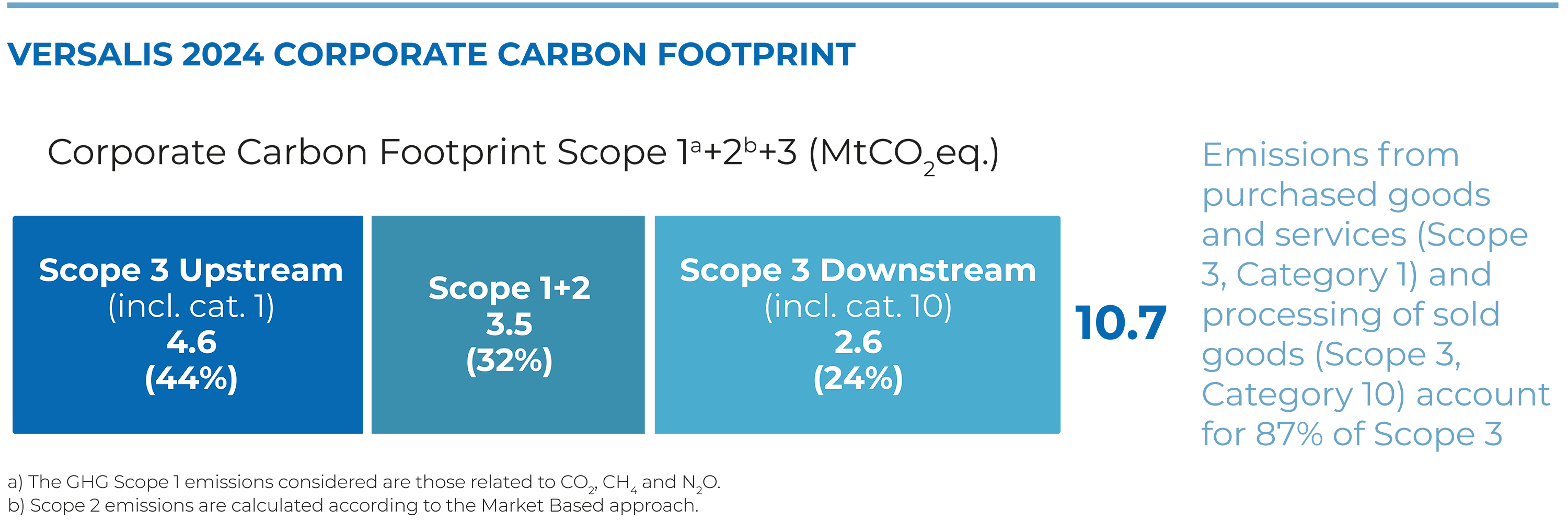

** The GHG Protocol is an international standard arising from the partnership between the World Resources Institute (WRI) and the World Business Council for Sustainable Development (WBCSD). It provides standards, guidelines, tools and training for business and government to measure and manage climate-warming emissions. It divides emissions into three scopes:

• Scope 1: direct emissions from company activities

• Scope 2: indirect emissions from energy purchases

• Scope 3: indirect emissions generated by activities along the entire value chain