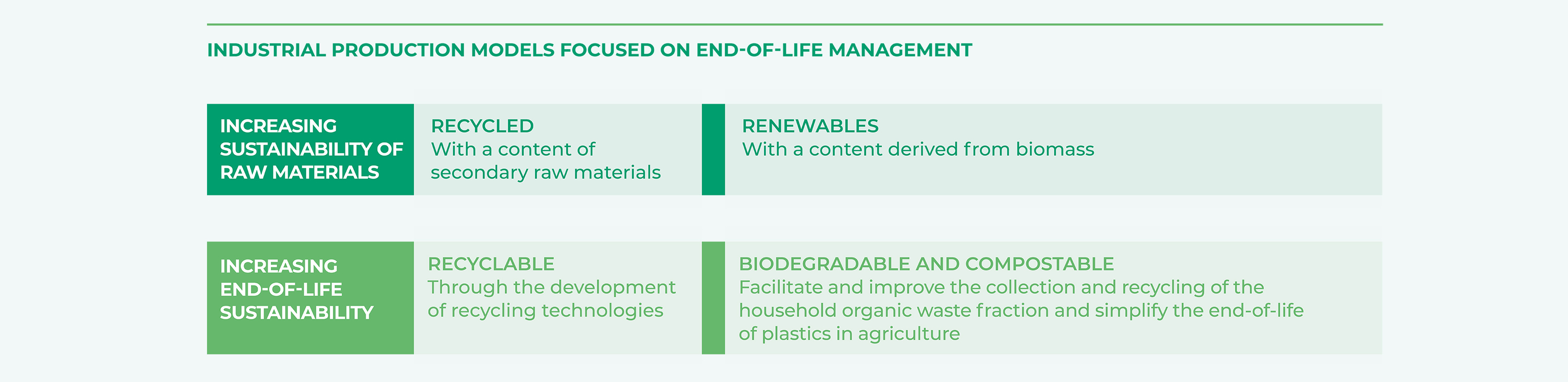

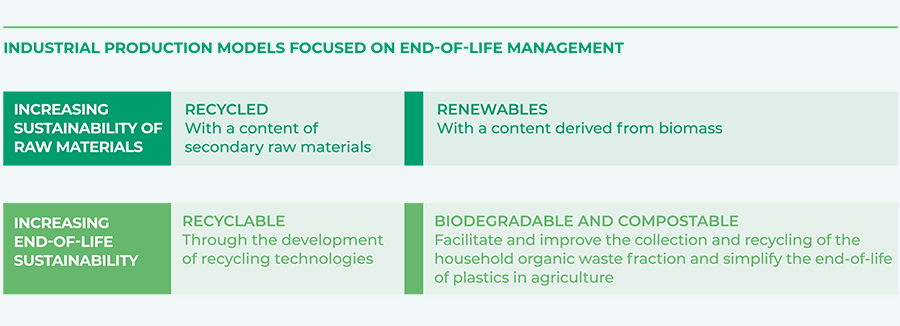

For us, the transition towards increased circularity represents a strategic lever in addressing current environmental challenges. This approach enables us to separate economic growth from the use of finite, non-renewable resources. To achieve this, we must reappraise business and manufacturing processes with clear objectives in mind: to reduce the use of natural resources, repurpose byproducts (manufacturing/production waste, scraps, emissions, discharges) by recycling or recovery and extend the useful life of products and assets through reuse and conversion.

We consider the entire supply chain: upstream, by sourcing alternative raw materials, and downstream, by developing complementary recycling technology for end-of-life products.