Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Climate, Infrastructure and Environment Executive Agency (CINEA). Neither the European Union nor the granting authority can be held responsible for them.

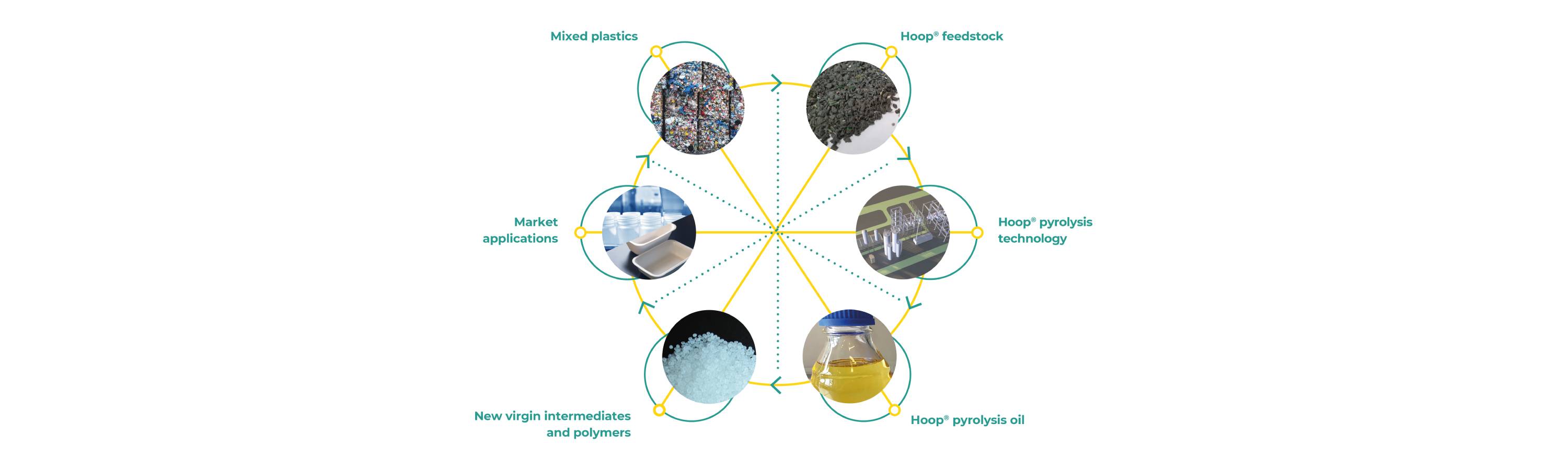

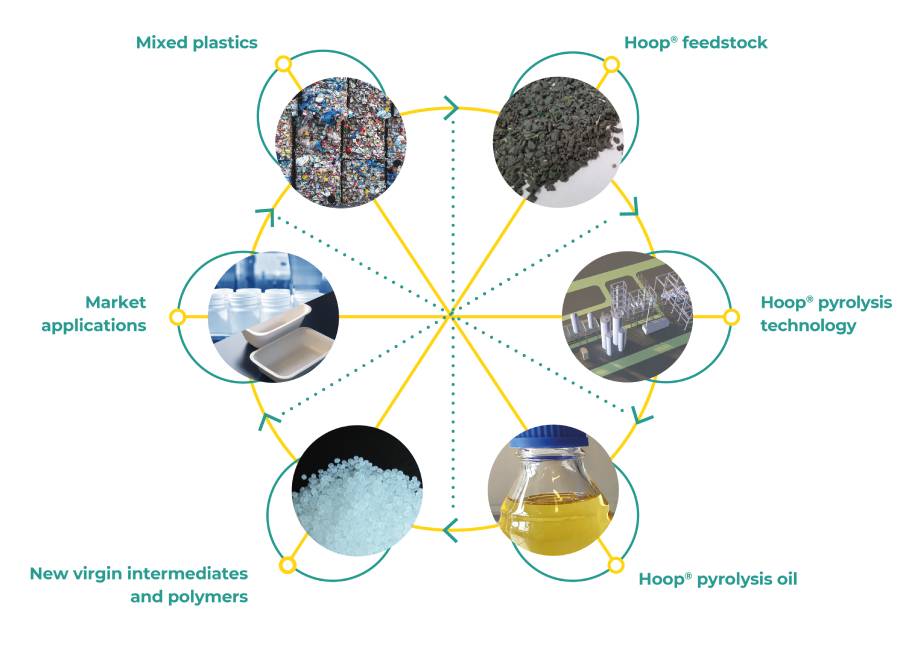

Chemical recycling for the sustainability of plastics

Watch the video

Leaflet The SC-HOOP Project

PDF 405.28 KB