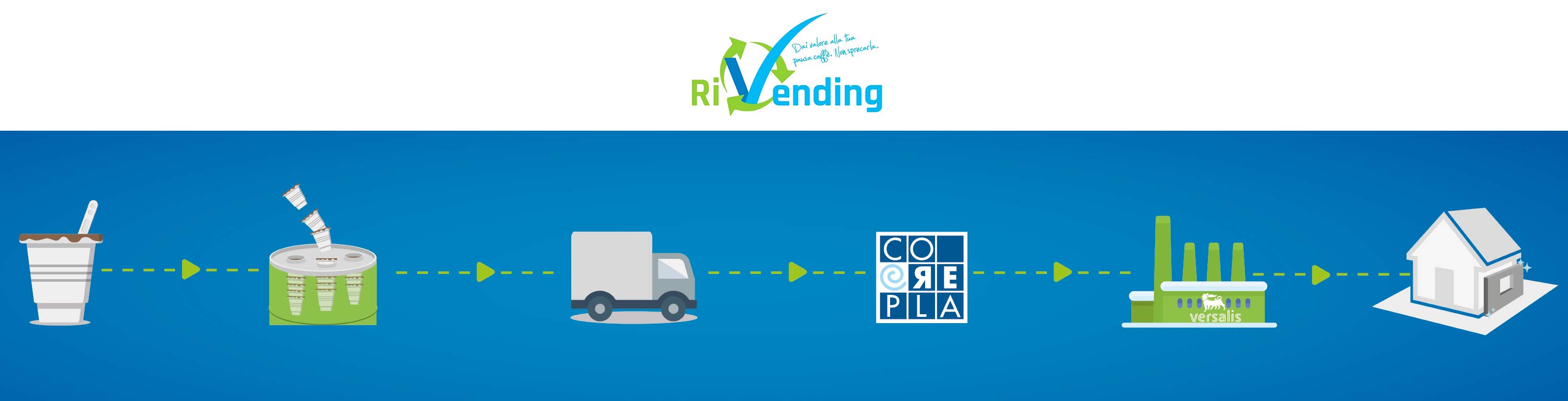

For us, the transition towards a circular economy is one of the main levers against the current environmental challenges of decoupling economic growth from the use of finite, non-renewable resources. Based on this approach, business and production processes are revisited, minimising the use of natural resources, reducing and adding value to waste (from production, waste, emissions, discharges) through recycling or recovery actions and by extending the useful life of products and assets through reuse or reconversion actions.

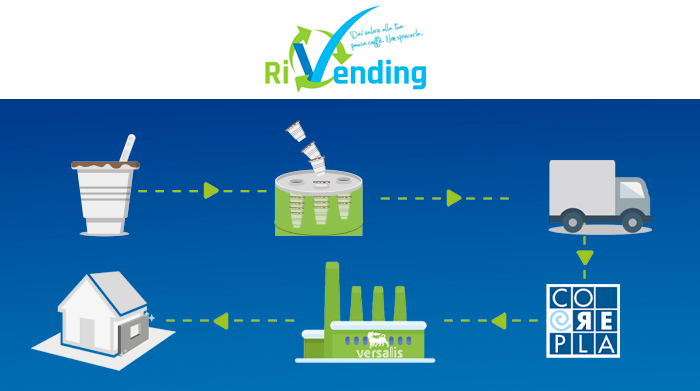

We are engaged in developing recycling solutions for plastics and rubbers. We enhance existing technologies by promoting the use of secondary raw materials and innovative sustainable products also through research and development of integrated technological platforms and partnerships with different players in the value chain.